Power quality is the degree to which voltage, frequency, and waveform remain within defined limits so electrical equipment operates reliably and efficiently. It reflects stable voltage magnitude, constant frequency, and a pure sinusoidal waveform that prevents malfunctions, overheating, and downtime.

At QSine Energy Solutions, we apply standards‑driven monitoring and mitigation practices to help industrial facilities maintain compliant, reliable power quality without disrupting operations.

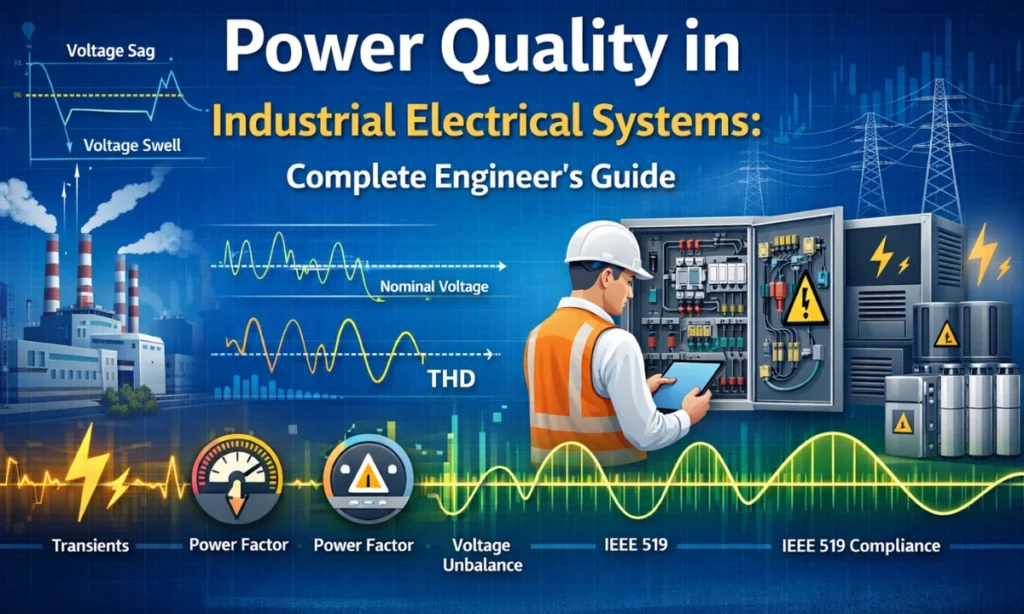

What are the common power quality issues in industrial settings?

Industrial environments are particularly susceptible to power quality problems due to the prevalence of heavy machinery, sensitive electronics, and dynamic loads. Addressing these issues is crucial for maintaining operational efficiency, preventing equipment damage, and avoiding costly downtime.

- Voltage Sags and Swells

Voltage sags and swells are short‑duration deviations in RMS voltage below or above nominal levels.

- Ranges: sags typically 10–90% of nominal for a half cycle to a few seconds; swells exceed 110%.

- Causes: sags from large motor starts or grid faults; swells from sudden load reduction or regulator issues.

- Effects: malfunctions, control errors, data loss, and damage in sensitive equipment.

- Harmonics and Total Harmonic Distortion (THD)

Harmonics are voltage or current distortions at integer multiples of the fundamental frequency, measured collectively as Total Harmonic Distortion (THD).

- Causes: nonlinear loads (VFDs, UPS, rectifiers, arc furnaces, welding machines).

- Effects: transformer/motor overheating, nuisance tripping, capacitor failures, reduced lifespan, communication interference.

Through our three decades of experience managing power systems, we’ve consistently observed that harmonic distortion is a primary cause of premature equipment failure and unexplained downtime.

- Transients (Surges/Spikes)

Transients are very short‑duration, high‑magnitude voltage or current spikes.

- Causes: lightning, utility switching, inductive load switching.

- Effects: instant electronics damage, insulation breakdown, data corruption, system resets.

- Poor Power Factor

Power factor is the ratio of real power (kW) to apparent power (kVA), indicating how effectively electrical power is converted into useful work.

- Causes: inductive loads (motors, transformers, arc welders).

- Effects: higher current for the same kW, increased I²R losses, overloaded circuits, higher bills (often demand charges), reduced system capacity.

- Voltage Unbalance

Voltage unbalance is the inequality of voltage magnitudes or phase angles in a three‑phase system.

- Effects (even at small percentages): reduced motor efficiency and shorter equipment lifespan due to increased losses/overheating.

- Causes: uneven single‑phase load distribution, faulty utility equipment, open phases.

Why is compliance with the IEEE 519 standard important?

IEEE 519 provides recommended limits for harmonic distortion on electric power systems.

- Preventing Equipment Damage: Limits help protect sensitive equipment within a facility and prevent adverse effects on the utility grid.

- Ensuring System Reliability: Reducing harmonics minimizes overheating and reduces the risk of nuisance tripping, leading to more reliable operations.

- Avoiding Utility Penalties: Many utilities impose penalties for excessive harmonic distortion, as it can impact their infrastructure and other customers.

- Optimizing Energy Efficiency: Lower harmonics contribute to reduced losses and improved energy efficiency.

How can power quality issues be identified and addressed?

Effective power quality management involves a systematic approach to identification, analysis, and mitigation.

- Power Quality Monitoring and Assessment

Power quality assessment is the process of monitoring and analyzing electrical parameters to detect performance issues. It uses analyzers to capture harmonics, sags, swells, transients, and power factor trends, enabling accurate diagnosis and targeted mitigation.

Deploy analyzers at strategic points to capture voltage, current, frequency, harmonics, power factor, and transients over time; analyze for root causes and impacts.

Our extensive experience providing turnkey solutions confirms that thorough, data‑driven assessments are essential for improving a facility’s electrical health.

- Power Factor Correction Techniques

Power factor correction improves system efficiency by reducing reactive power flow and stabilizing voltage.

- Capacitor banks (fixed or automatic) provide reactive power to offset inductive loads.

- SVCs/SVGs offer dynamic, fast compensation for varying loads; SVGs provide finer control.

- Harmonic Mitigation Techniques

Harmonic mitigation techniques reduce distortion from nonlinear loads to enhance equipment longevity and system efficiency.

- Passive Filters: Tuned L‑C‑R to shunt specific harmonic frequencies; cost‑effective, but can resonate and are less flexible for varying loads.

- Active Harmonic Filters (AHF): These power electronics devices actively inject a cancelling current into the system, effectively eliminating harmonic distortion caused by non-linear loads. AHFs are highly effective, adaptable to changing loads, and prevent resonance issues.

- Voltage Variation Solutions

Voltage variation solutions maintain stable voltage supply to sensitive loads.

UPS systems provide conditioned backup power, while DVRs inject corrective voltage to handle sags and swells.

- UPS: converts AC–DC–AC to deliver continuous, clean power; protects against sags, swells, transients, and outages.

- DVR: series‑connected device that injects voltage to compensate sags/swells without interrupting power.

- Surge Protection Devices (SPDs) and Grounding

Surge Protection Devices divert transient overvoltages to ground; robust grounding ensures safe fault current paths and mitigates noise/transients.

- Surge Protection Devices (SPDs): These devices divert transient overvoltages (surges) to ground, protecting sensitive equipment from damage. SPDs should be installed at various points in the electrical system, from the service entrance to individual loads.

- Proper Grounding: A robust and correctly designed grounding system is fundamental to good power quality, providing a safe path for fault currents and helping to mitigate noise and transients.

Our strategic advice, refined over decades of delivering uninterrupted clean‑energy solutions, consistently emphasizes grounding as the foundation of reliability and equipment protection.