Power factor correction is the standard remedy for avoiding utility penalties and reducing high KVAH energy bills, but implementing it incorrectly can be a costly mistake. To fix efficiency issues, the traditional move has always been simple: install a Power factor capacitor bank.

Every plant manager knows the rule: Low Power Factor = Penalties + High KVAH Energy bill

To fix this, the standard solution has always been simple, install a Power Factor Capacitor bank.

But in today’s modern industrial environment, this “simple” fix can be dangerous.

If your facility uses VFDs, LED lighting, or UPS systems, your grid is likely polluted with Harmonics. When you add standard capacitors to a harmonic-rich system, you risk creating a condition called Resonance. This can cause capacitors to overheat, bulge, or even explode.

- Need a refresher? If you aren’t sure what Harmonics are yet, read our guide: What are Harmonics in Electrical Systems?

Key Takeaways

- Capacitors Can Fail: Installing standard power factor capacitors in harmonic-rich environments (with VFDs or UPS) often leads to premature failure due to low impedance at high frequencies.

- Resonance Danger: The interaction between grid inductance and capacitance can create parallel resonance, amplifying harmonic currents by up to 20x.

- Detuned Reactors: A detuned reactor is an inductor placed in series with a capacitor to “reject” harmonics, allowing for safe power factor improvement in polluted grids.

- SVG Technology: Static Var Generators (SVG) provide the fastest, safest correction for lagging power factor because they do not rely on passive capacitors and cannot resonate.

- Audit First: Before buying an APFC panel, measure your Total Harmonic Distortion (THD). If THD-v is >5% or THD-i is high, a standard bank is unsafe.

What is Power Factor Correction?

Power Factor (PF) is a measure of efficiency—how much of the electricity you pay for is doing useful work.

- Unity PF (1.0): 100% efficiency. All power is used for work.

- Lagging Power Factor (<0.9): Inefficiency caused by inductive loads like motors and transformers. They consume “Reactive Power” (kVAr) to create magnetic fields.

The Traditional Fix: Capacitors

To fix lagging power factor, engineers install capacitor banks (APFC Panels). Capacitors act as a local source of reactive power, so the utility grid doesn’t have to supply it. This raises your PF and eliminates penalties.

Capacitors are excellent for Power Factor Improvement—but only if the power quality is clean (low harmonics).

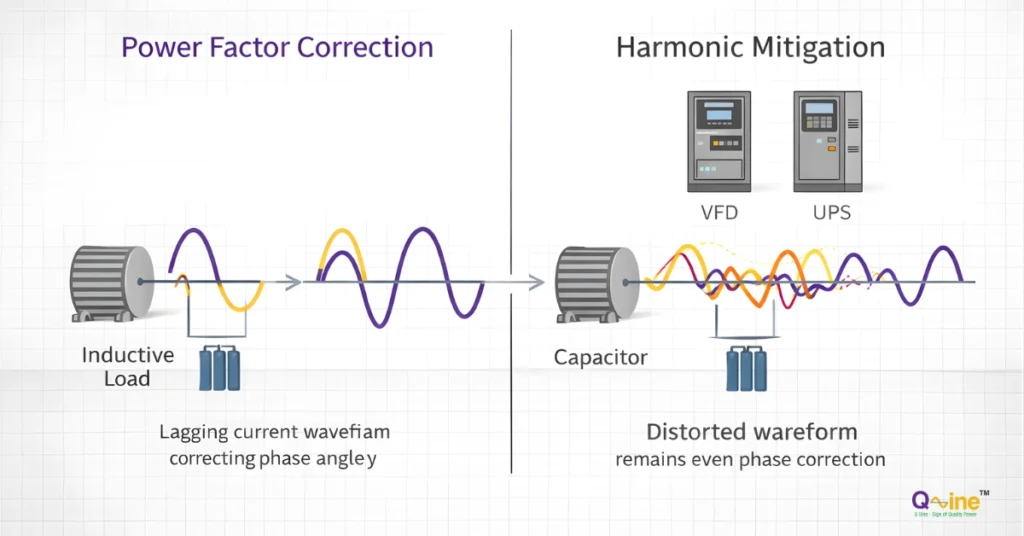

Is Power Factor Correction the Same as Harmonic Mitigation?

No. They are two completely different power quality issues, though they often affect each other.

- Power Factor Correction is about Quantity (Efficiency). It minimizes the phase angle difference between voltage and current to ensure you are using the power you pay for. It addresses displacement.

- Harmonic Mitigation is about Quality (Purity). It removes distortions from the electrical waveform to ensure smooth sinusoidal power. It addresses distortion.

The Trap: Many facility managers assume that installing a standard APFC panel solves all power issues. It doesn’t. An APFC panel improves efficiency but does nothing for distortion. In fact, without reactors, it often makes distortion worse by creating a path for resonance.

The Hidden Danger: When Capacitors Meet Harmonics

Here is the problem: Standard capacitors act as sinks for harmonics.

Harmonic currents naturally seek the path of least impedance. Unfortunately, a capacitor’s impedance decreases as frequency increases.

- To a 50Hz fundamental current, a capacitor looks like a wall (High Impedance).

- To a 250Hz (5th Harmonic) current, a capacitor looks like a drainpipe.

If you install a standard capacitor bank in a facility with high harmonics (e.g., many VFDs), the capacitor will suck in all those high-frequency currents. It will overload, overheat, and fail prematurely.

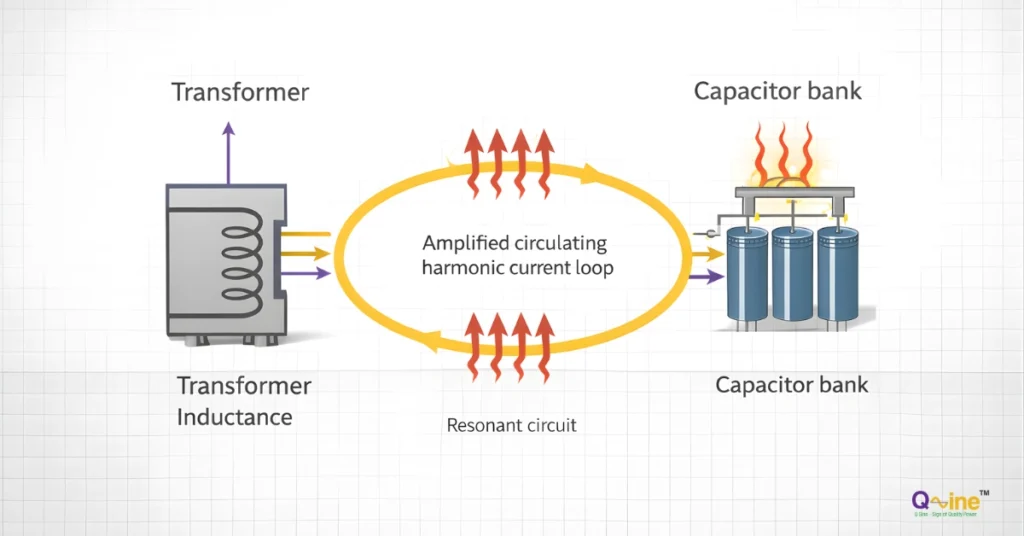

What is Harmonic Resonance?

It gets worse. The interaction between your transformer (inductance) and your new capacitor bank (capacitance) creates a natural resonant frequency.

If this resonant frequency matches one of your harmonic frequencies (like the 5th or 7th harmonic), Parallel Resonance occurs.

What Happens During Resonance?

- Current Amplification: The harmonic currents circulating between the transformer and capacitor can multiply by 10x or 20x.

- Voltage Spikes: Your system voltage can spike dangerously high, destroying sensitive electronics (PLC cards, VFDs).

- Catastrophic Failure: The capacitor’s bank fuses blow, or the capacitors themselves rupture violently.

Engineering Warning:

If your facility has VFDs or non-linear loads totaling >15% of your transformer capacity, NEVER install standard capacitors. You need a detuned solution.

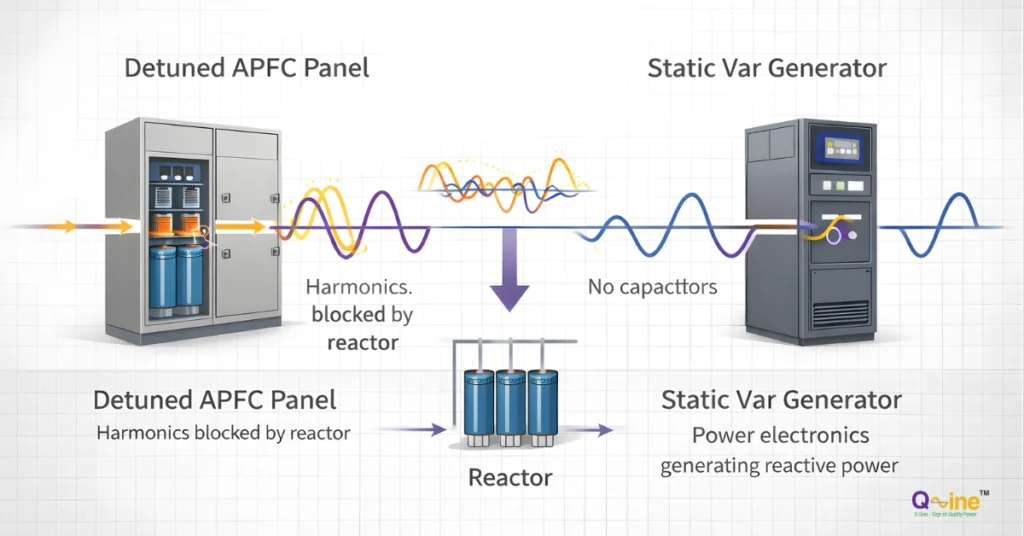

The Solution: Detuned Reactors & SVGs

So, how do you fix Power Factor without blowing up your equipment? You have two modern options.

1. Detuned APFC Panels (Capacitor + Reactor)

By adding a Detuned Reactor (an inductor) in series with the capacitor, we change physics.

- How it works: The reactor increases impedance at high frequencies.

- Result: The capacitor still provides reactive power at 50Hz (fixing PF) but “rejects” the high-frequency harmonics (preventing resonance).

- Best For: Facilities with moderate harmonics (15% – 50% non-linear load).

2. Static Var Generators (SVG)

This is the advanced, electronic replacement for capacitors.

- How it works: An SVG uses power electronics (IGBTs) to generate reactive power instantly. It has no capacitors, so there is absolutely zero risk of resonance.

- Best For: Highly dynamic loads (welding, cranes) or extremely high harmonic environments.

- See the Tech: Explore Q Sine’s [SVG and Active Solutions] for specs. (Internal Link to Product Page)

Comparison: Standard APFC vs. Detuned APFC vs. SVG

Which solution is right for your plant?

| Feature | Standard APFC (Capacitor Only) | Detuned APFC (Reactor + Cap) | Static Var Generator (SVG) |

| Technology | Pure Capacitors | Capacitor + Inductor | IGBT Power Electronics |

| Resonance Risk | High (Dangerous) | Low (Safe) | Zero (Immune) |

| Response Time | Slow (Seconds) | Slow (Seconds) | Instant (< 5ms) |

| Life Span | Low (if harmonics exist) | Medium | High |

| Best Application | Clean Grid Only | General Industry | Heavy Automation / Welding |

Conclusion

Power Factor Correction is essential but doing it blindly is dangerous and expensive. If you simply ask for “a capacitor bank,” you might be buying a ticking time bomb.

The Rule of Thumb:

- Clean Power? Standard Capacitors are fine.

- Dirty Power (VFDs)? You must use Detuned Reactors or SVGs.

Don’t guess. At Q Sine, we start with measurement, not assumptions! Every solution is preceded by a harmonic audit to ensure long-term reliability.

Avoid Resonance Risk Today. Consult Q Sine for a Safe Power Factor Solution

Frequently Asked Questions (FAQs)

Can I just add a reactor to my existing capacitor bank?

Usually, no. Adding a reactor changes the voltage across the capacitor (voltage rise effect). Your existing capacitors (likely rated for 440V) may need to be replaced with higher-rated ones (e.g., 480V or 525V) to handle a detuned reactor safely.

What is the lagging power factor caused by?

Lagging power factor is caused by inductive loads such as induction motors, transformers, and welding machines. These devices consume reactive power to create magnetic fields, lowering your system’s efficiency.

Is an SVG better than a capacitor bank?

Yes, in almost every technical way. An SVG (Static Var Generator) provides stepless, instant correction and is immune to resonance. However, it has a higher upfront cost compared to a traditional capacitor bank.

Do I need a reactor with my capacitor?

If your facility uses Variable Frequency Drives (VFDs), LED lighting, or UPS systems, the answer is YES. Installing capacitors without reactors in these environments creates a high risk of resonance, which can destroy the capacitors and damage other equipment. Always use a Detuned APFC or SVG in modern industrial plants.