Active Harmonic Filters (AHF) and their passive counterparts are the primary line of defense for industrial power systems, but choosing the wrong technology can be a costly mistake. If you have identified high Total Harmonic Distortion (THD) in your facility, you know you have a problem. The question isn’t if you need a filter, it’s which one offers the best protection and ROI for your specific machinery.

If you have identified high Total Harmonic Distortion (THD) in your facility, you know you have a problem. The question isn’t if you need a filter—it’s which one offers the best protection and ROI for your specific machinery.

For decades, passive filters were the standard. But in today’s era of heavy automation, robotics, and Variable Frequency Drives (VFDs), the rules have changed. Choosing the wrong filter can lead to resonance, leading power factor issues, and even equipment damage.

New to Harmonics? If you aren’t sure what THD is yet, start by reading our guide: What are Harmonics in Electrical Systems?

The Core Difference: Active vs. Passive

Before diving into specs, it is crucial to understand the fundamental difference in operation.

- Passive Harmonic Filters (PHF): Think of these as a “Fixed Barrier.” They are tuned to block one specific frequency (usually the 5th or 7th). They are static and “dumb”—they do not react to changes in your load.

- Active Harmonic Filters (AHF): Think of these as “Noise-Canceling Headphones” for your power grid. They are dynamic and intelligent—they monitor the grid in real-time and actively cancel distortion, no matter how much it fluctuates.

Passive Harmonic Filters: The Old Guard

A passive filter consists of inductors and capacitors (L-C circuit) tuned to a low impedance at a specific harmonic frequency.

Pros:

- Lower Initial Cost: Simple construction makes them cheaper upfront.

- Reliability: Few moving parts or electronics fail.

Cons (The Hidden Risks):

- Fixed Capacity: If your load drops (e.g., a VFD running at 30%), the filter may provide too much reactive power, causing a Leading Power Factor, which utilities often penalize.

- Size: They are physically bulky and heavy.

- Resonance Risk: If the grid conditions change, passive filters can interact with grid impedance, causing resonance that amplifies harmonics instead of reducing them.

Rule of Thumb:

Passive filters are generally only recommended for loads that never change, such as large ventilation fans or pumps that run at 100% speed, 24/7.

Active Harmonic Filters (AHF): The Modern Standard

For modern industries—especially Textile, Cement, and Data Centers—loads are never constant. VFDs ramp up and down, and machines cycle on and off. This requires a solution that adapts instantly.

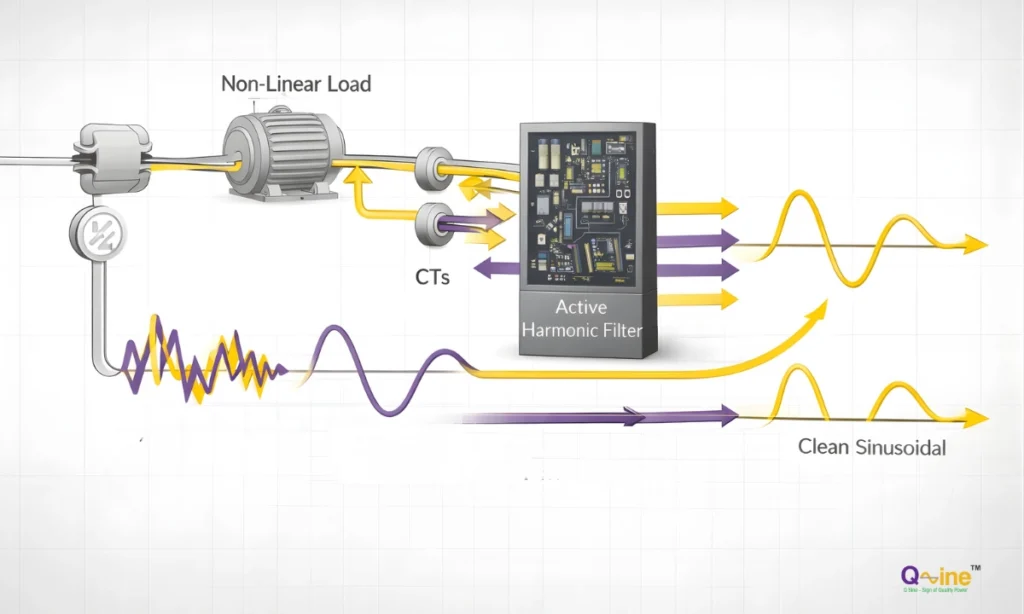

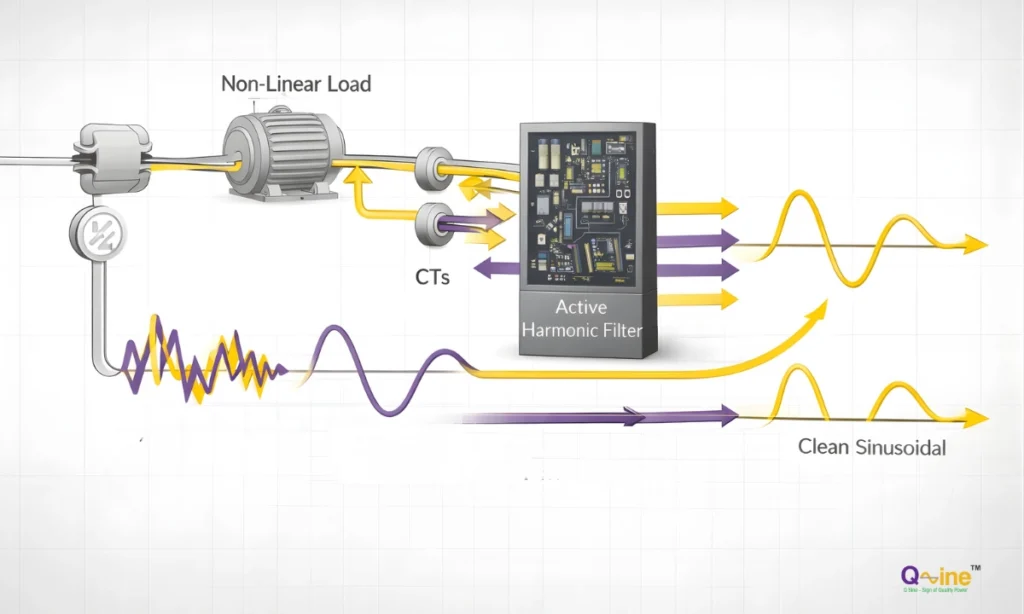

How An Active Harmonic Filter Works

The AHF Panel uses Current Transformers (CTs) to measure the harmonic current on the line. It then generates an equal but opposite current spectrum and injects it back into the line.

- +5 Amps of Harmonic Noise (from load)

- -5 Amps of Canceling Current (from AHF)

- = 0 Amps Distortion (clean sine wave)

Key Benefits for Industry

- Stepless Correction: The AHF adjusts its output from 0% to 100% seamlessly. It never over-compensates.

- Multi-Tasking: A single Q Sine AHF panel can correct Harmonics, Power Factor, and Load Unbalance simultaneously.

- Immunity to Resonance:. Because it relies on active electronics rather than passive components like capacitor and Inductor, it cannot cause harmonic resonance, with further eliminating voltage / current amplification.

Which Harmonic Filter Is Best for Industrial Power Systems?

In modern industrial power systems characterized by heavy automation, robotics, and fluctuating demand, static solutions typically fall short. Passive filters operate on fixed parameters, making them unable to adapt when VFDs ramp up or down. This rigidity often leaves the system unprotected during peak distortion events or over-compensated during idle periods.

Consequently, for any facility relying on non-linear loads where the harmonic profile shifts throughout the production cycle, a dynamic solution is required. The “best” filter is one that can track these changes instantly mitigating harmonics, correcting power factor, and balancing loads simultaneously to maintain grid stability regardless of operational variance.

Detailed Comparison Matrix

| Feature | Passive Harmonic Filter | Active Harmonic Filter (AHF) |

| Load Handling | Fixed / Constant Loads Only | Dynamic / Variable Loads (VFDs) |

| Harmonic Mitigation | Specific Order Only (e.g., 5th) | All Orders (2nd to 51st) |

| Response Time | Slow / Static | < 5 Milliseconds (Instant) |

| Power Factor | Risk of Leading PF at low loads | Maintains Unity PF (0.99) |

| Resonance Risk | High | None |

| Size / Footprint | Large & Heavy | Compact, Modular & Scalable |

For industrial facilities utilizing Variable Frequency Drives (VFDs) and dynamic automation, Active Harmonic Filters (AHF) are the technically superior choice.

Unlike passive solutions, AHFs provide real-time, stepless mitigation that adapts to fluctuating loads, ensuring compliance with IEEE 519 standards without the risk of system resonance or leading power factor during low-load conditions.

Passive filters remain a viable option only for applications with large, constant, and non-fluctuating loads.

Verdict: If your facility uses VFDs, UPS systems, or automated robotics, a Passive Filter is unsafe. An Active Harmonic Filter is the only technically sound choice.

Why Q Sine AHF Panels Are the Industry Choice

At Q Sine, we don’t just assemble panels; we engineer solutions for the harshest industrial environments. Our Active Harmonic Filter Panels are built to outperform standard off-the-shelf units.

1. Modular Scalability

Start with what you need with minimum block size (typically 30/60/100A) then further add the modules as per the demand requirement. It also gives flexibility for unlimited parallel operation.

2. High Efficiency Architecture

Our 3-Level Topology ensures high efficiency and minimal losses, meaning the filter itself consumes negligible power while cleaning your grid.

3. Smart HMI Display

Every Q Sine AHF comes with a 7-inch Touchscreen HMI. You can see your THD levels drop in real-time, view waveforms, and download data logs for your compliance audits.

Visit our Active Harmonic Filter Product Page for full datasheets and capacity options.

Engineering Note: Caution with Passive Solutions

Passive filters are “tuned” L-C circuits designed for a specific load profile and grid impedance. If your plant adds new machinery or if the utility grid impedance shifts, these filters can detune or create a resonance condition, amplifying harmonics rather than reducing them. They should generally be avoided on buses with highly variable loads.

ROI Calculation: Is Active Worth the Cost?

It is true: An Active Harmonic Filter costs more upfront than a Passive one. But the Return on Investment (ROI) usually takes less than 24-18 months.

How does it pay for itself?

- Preventing Downtime: A single harmonic-induced failure (e.g., a blown VFD card) can halt production for hours. The cost of one outage often exceeds the price of the filter.

- Energy Reduction: By eliminating harmonic currents, you reduce “Skin Effect” losses in cables and Eddy Current losses in transformers. This directly lowers your electricity bill.

- Capacitor Safety: It protects your existing capacitor banks from exploding due to resonance.

Concerned about your capacitors? Read why standard capacitors are at risk in our guide: Power Factor Correction vs. Harmonic Mitigation

Regulatory Compliance & Utility Constraints

Beyond internal equipment protection, effective harmonic mitigation is often a regulatory necessity. Many utility providers and electricity boards now strictly enforce IEEE 519-2014 limits at the Point of Common Coupling (PCC).

Facilities found exceeding Total Demand Distortion (TDD) limits face increasing scrutiny, ranging from surcharge penalties to potential disconnection notices until corrective measures are installed.

Conclusion

In the battle of Active vs. Passive, the winner is determined by your load.

- If you run a giant water pump at constant speed, save money and buy Passive.

- If you run a modern factory with VFDs, automation, and fluctuating power demands, you need Active.

Don’t risk purchasing a filter that creates more problems than it solves. Let Q Sine engineer the right protection for your assets.

Ready to Clean Your Power? Get a Quote for Q Sine Active Harmonic Filters

Frequently Asked Questions

When should I use an active harmonic filter over a passive one?

You should use an Active Harmonic Filter (AHF) when your facility has variable loads (like VFDs, elevators, or welding machines) or when space is limited. Passive filters are restricted to large, constant loads that do not fluctuate.

What is the efficiency of a Q Sine AHF panel?

Q Sine Active Harmonic Filter panels operate with high efficiency (Generally above 98%), ensuring minimal energy loss while effectively mitigating harmonics up to the 51st order.

Can an AHF panel improve power factor?

Yes. In addition to filtering harmonics, an AHF panel provides stepless reactive power compensation, improving your power factor to near unity (0.99) without the risk of resonance often found with capacitor banks.