Load Flow Analysis Services by Q Sine

Load Flow Analysis ensures proper sizing of cables, transformers, and voltage profile settings.

Q Sine EXPERT SERVICES

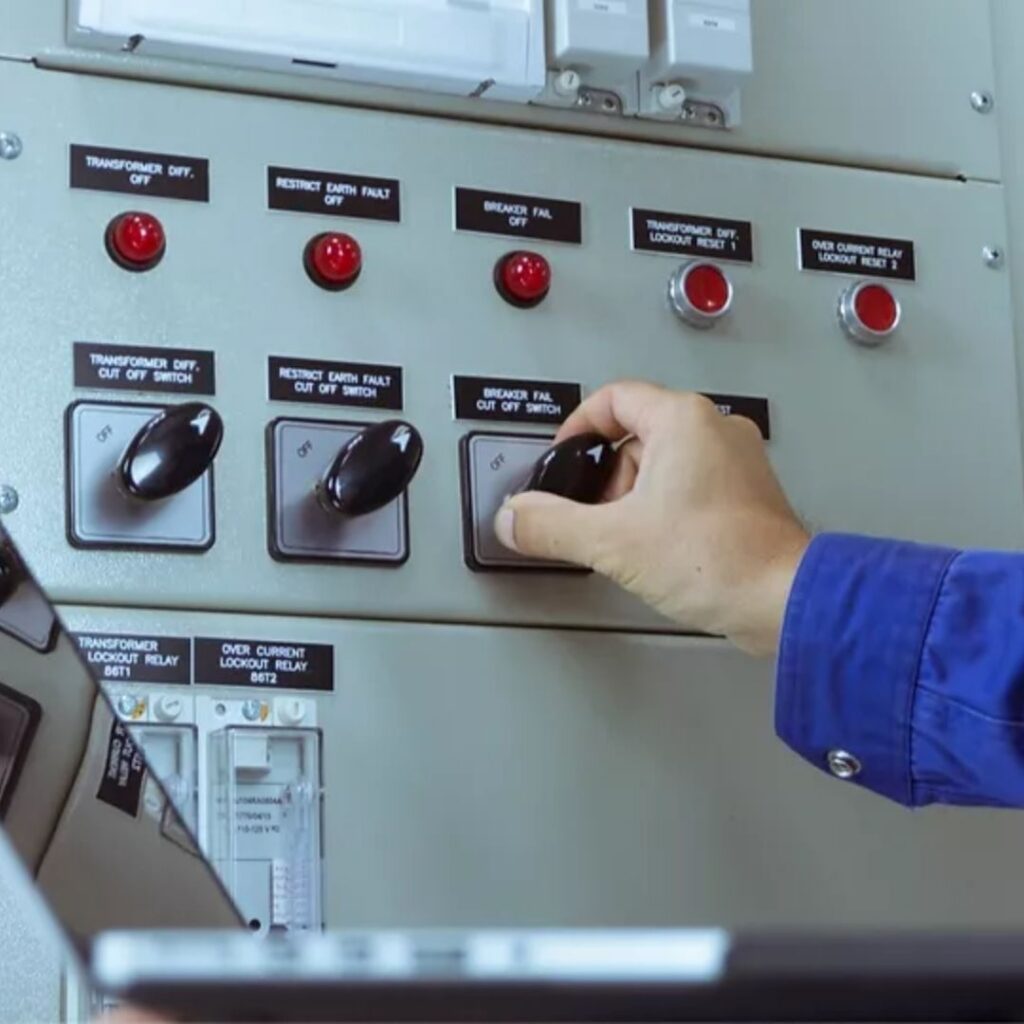

Load Flow Analysis Services by Q Sine

Load flow study is the steady state analysis of power system network which determines the operating state of the system for a given loading. It’s goal is to determine the flow of power, current, voltage, real power and reactive power in a system under any load conditions. During the design phase of a new project or when evaluating changes and additions to existing electrical system, a load flow study is necessary to ensure system voltages and current remain within safe limits and whether additional equipment or services will be required. The flow of electric power in any electrical system is referred to as “Load Flow”

- Voltage and Power Level Maintenance

- Power Flow Study

- AC Power Focus

- Steady-State Operation

- Software Implementation

- Future Planning

- Optimal Operation

- Key Metrics

Other Services

Q Sine offers power quality enhancement & power continuity solutions

Annual Maintenance Contracts

We offer our specialised services for the equipment of various Brands and Makes.

Power Quality Audit Service

Q Sine specialises in conducting PQA and makes analysis of the data. Based on which the solution is worked out.

Rental Equipment Services by Q Sine

We offer various Power equipment on rental basis (short and Long duration) to cater your requirement.

Arc Flash Study Services by Q Sine

Arc Flash Risk Assessment protects employees from electric arc flash hazards in industrial settings.

Short Circuit / Relay Coordination Study Services by Q Sine

Relay coordination study optimizes protection device settings to minimize faults and ensure reliable power.

Industries we serve

Manufacturing

Automobile

Foundry

Hospitals

Packaging

Sugar Mills

Pharma

Datacenters

Textiles

FMCG

Agro Industries

Metal, Mineral & Mines

Case Studies

Sandvik Asia, Pune (End User)

- Load Details : Industrial machines

- Before condition : Initially Current THD was observed to be 15%.

- Solution / Proposal : Proposed 100 Amp AHF - 2 units

- After Solution : Current THD reduced to 6%

Sagar Manufacturers Pvt Ltd (SMPL), Bhopal

- Load Details : Spinning mill machines

- Before condition : Initially Current THD was observed to be 15%

- Solution / Proposal : Proposed 150 Amp AHF - 5 units and 300 Amp AHF - 6 units

- After Solution : Current THD reduced to 7%

Fresenius kabi India Pvt. Ltd, Pune

- Load Details : Machines Application (Pharma)

- Before condition : Power factor was a major concern which was about 0.97

- Solution / Proposal :Proposed 510 KVAR Hybrid panel with 400 KVAR RTPFC & 110 KVAR lead / lag step less power factor correction ( SVG ) Panel

- After Solution : PF improved to 0.995

Sampada Paper Mill, Sangli

- Load Details : Craft paper mill machines

- Before condition :Initially Current THD was observed to be 18% & VTHD 3.2%

- Solution / Proposal : Proposed 200 Amp AHF unit

- After Solution : Current THD reduced to 7% & VTHD reduced to 2.5%

Yash Industries Maharashtra

- Load Details : CNC machines

- Before condition : Power factor concern

- Solution / Proposal : Active correction of PF by SVG

- After Solution : PF improved to 0.995

Kisan Agro, Maharashtra

- Load Details : VFD and motors

- Before condition : Harmonics & Power factor concern

- Solution / Proposal : Active correction of PF by SVG and Harmonics by AHF

- After Solution : PF improved to 0.995 & met IEEE 519:2014 standard for Harmonics